H-Beam Shelf

Company Name:

State Academy of Fine Arts in Stuttgart

Category:

product design

Project description:

The H-Beam Shelf is a series of wall shelves specially designed for distributed / decentralised production in terms of materials and manufacturing.

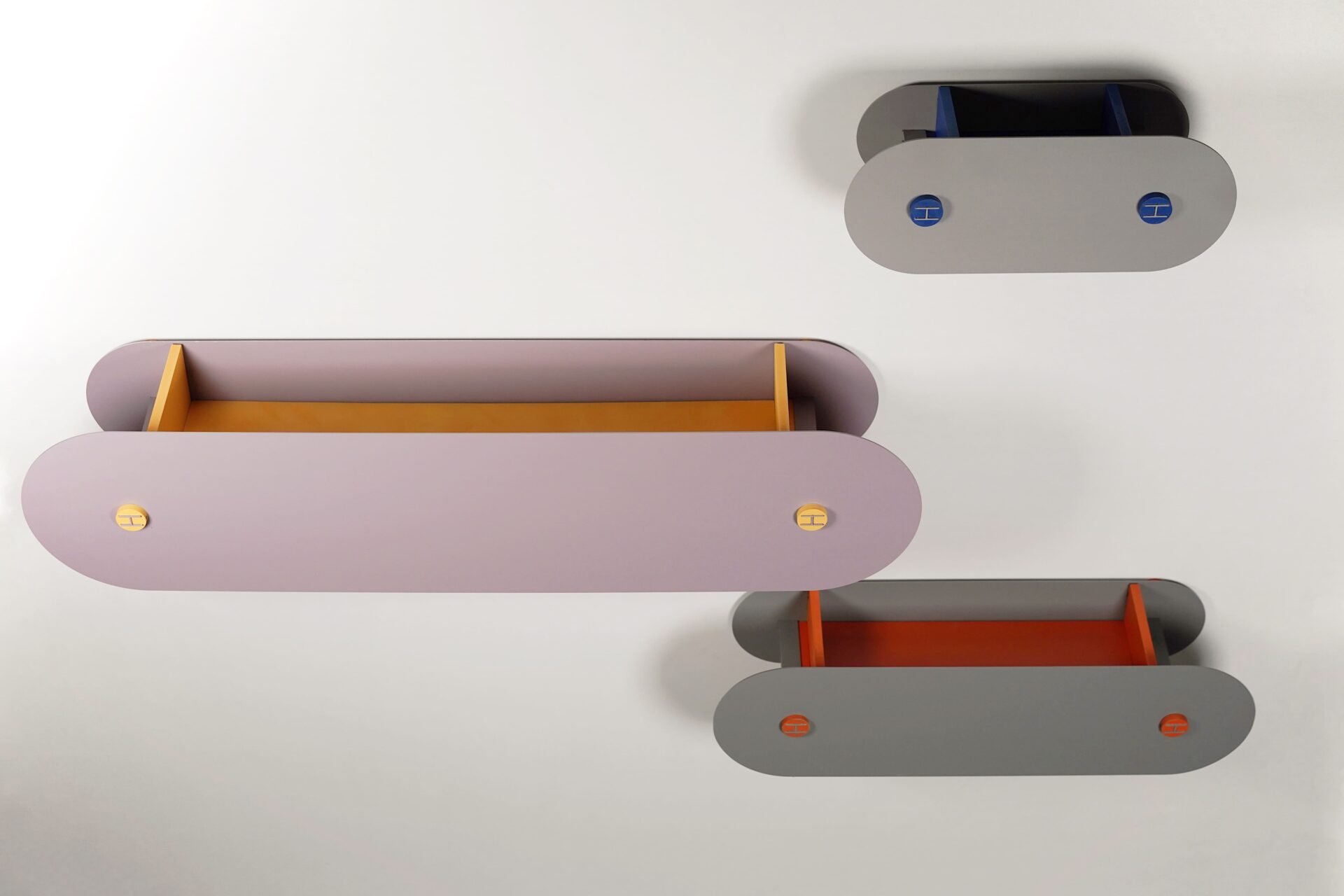

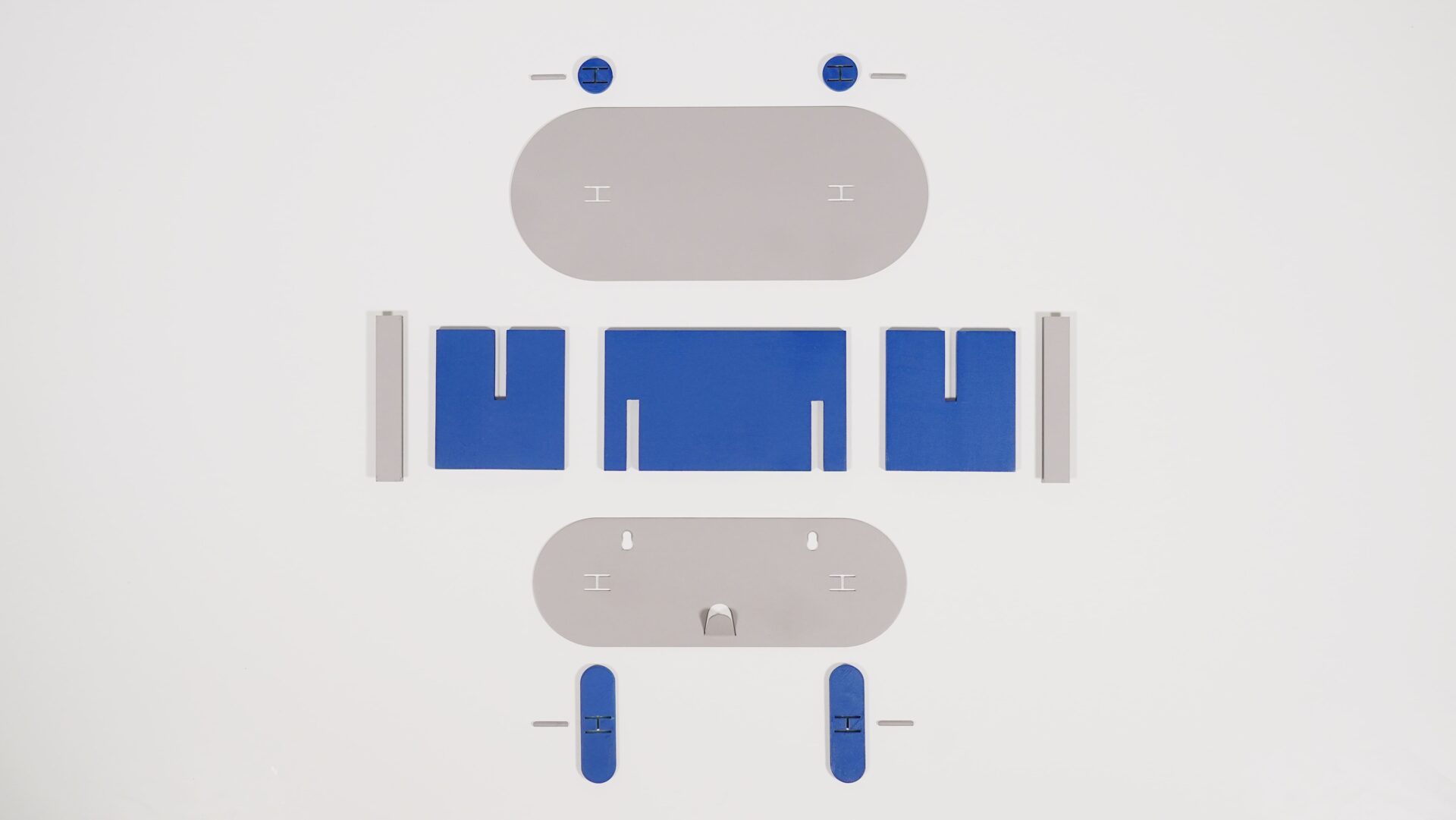

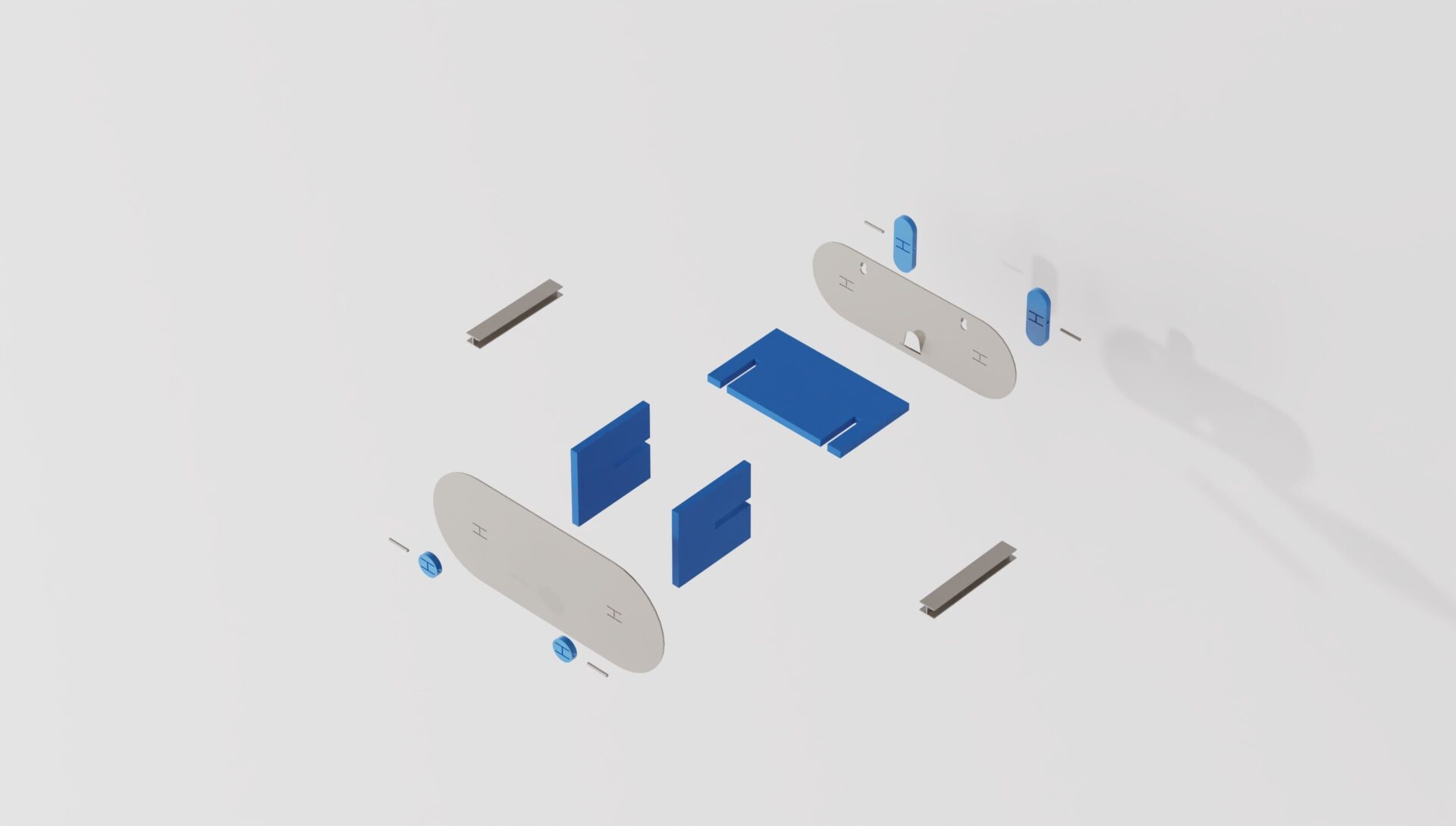

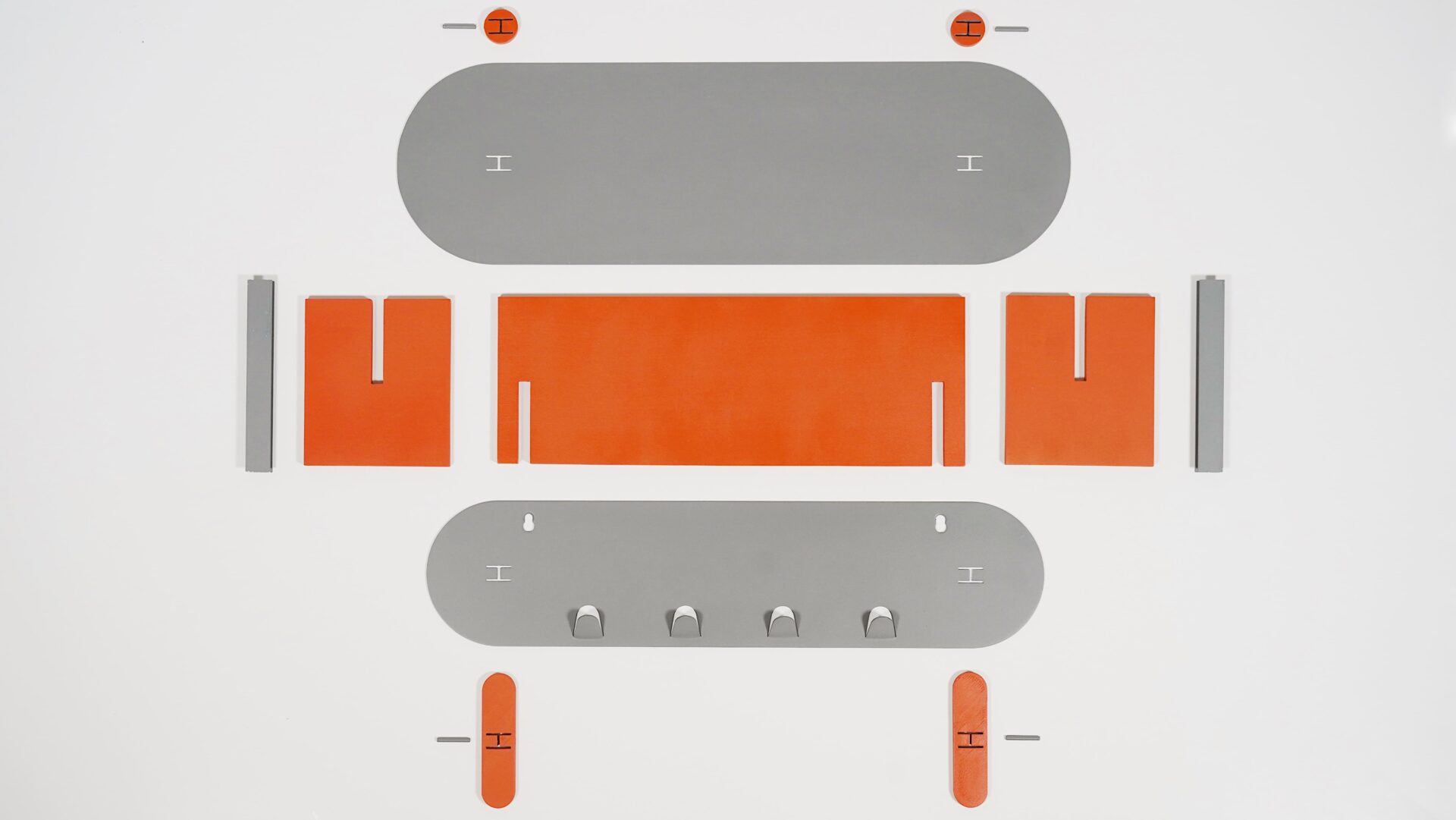

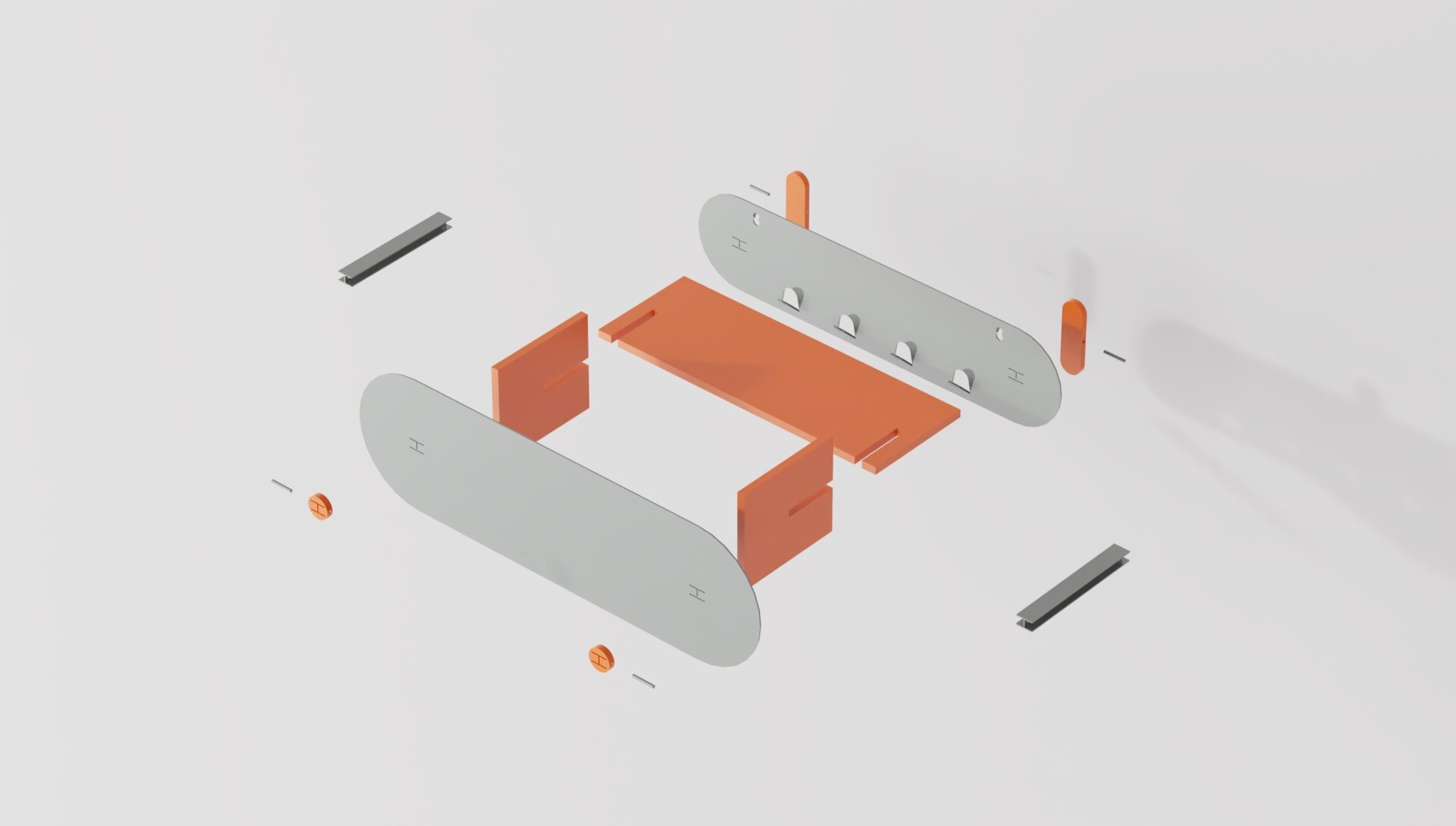

It uses two H-beams as main supports, connecting two oblong shaped aluminium panels at the front and back. The shape of the H-beam also cleverly constrains the centre shelf made of Ureol.

The 3d-printed fasteners are attached to the two ends of the H-beam. The inserted metal pins in the middle hold the whole structure in place.

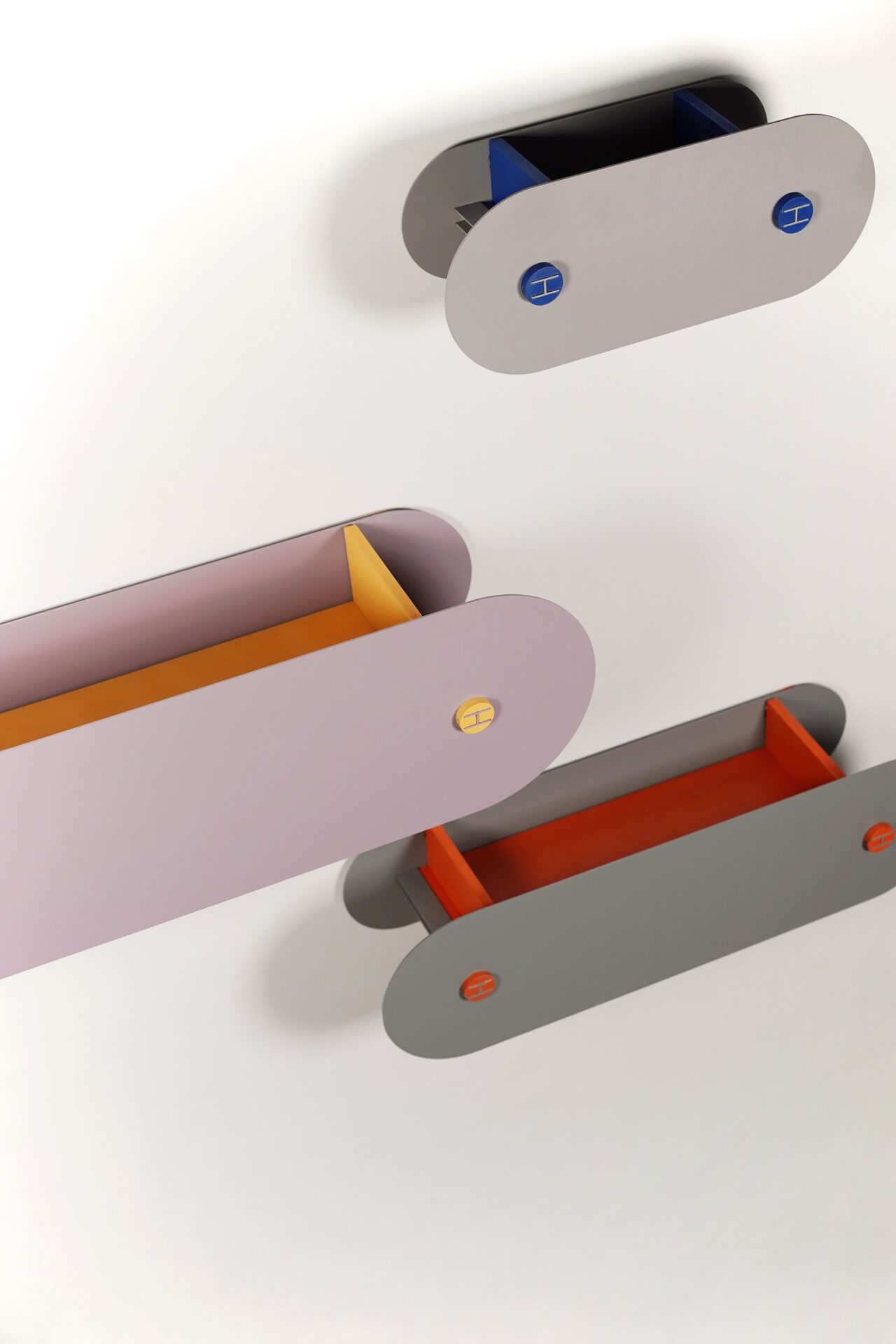

The oblong plate on the front also hides the shelves and hooks, so it looks neat even if something is put on it. The whole product is available in three sizes for different scenarios.

It is made only of H-beam, laser-cut aluminium sheets, CNC-milled Ureol( modelling board) and 3D-printed parts. All materials are highly accessible and easy to manufacture, and the whole product can be saved as a file and produced by computer.

What makes it smart / innovative?:

The Design of H-Beam Shelf is based on the context of distributed/ decentralised production.

With the increasing popularity of affordable, digitally controlled manufacturing processes, there are more and more opportunities to mass produce a product without having to resort to traditional production chains.

The concept of distributed manufacturing is replacing as much of the physical supply chain as possible with digital information, and it has several obvious advantages: independence, affordability, and most importantly, sustainability.

I would also like to get involved from a designer’s point of view and use this distributed manufacturing mindset to do design.

Why is it relevant for the final user?:

Products designed with the concept of distributed manufacturing are suitable for small and local production, which means that each city may have the capacity to produce them.

Being able to go from placing an order to receiving the goods from the local manufacturer is a fast process for the user, as there is no need to go through long waiting in the global shipping chain.

In addition, because some of the labor costs and non-essential transportation costs can be eliminated (e.g., traditional manufacturing chains may require collecting various materials, roughing them in one place and finishing them in another, resulting in many unnecessary transportation steps that increase costs and waste energy), the final product can be more affordable than similar products.

Link to the project:

https://drive.google.com/file/d/1VBHb6v1yPdOKw-nJtgNsPS1nXagMKa4K/view?usp=sharing

Pdf presentation: